1. Model establishment

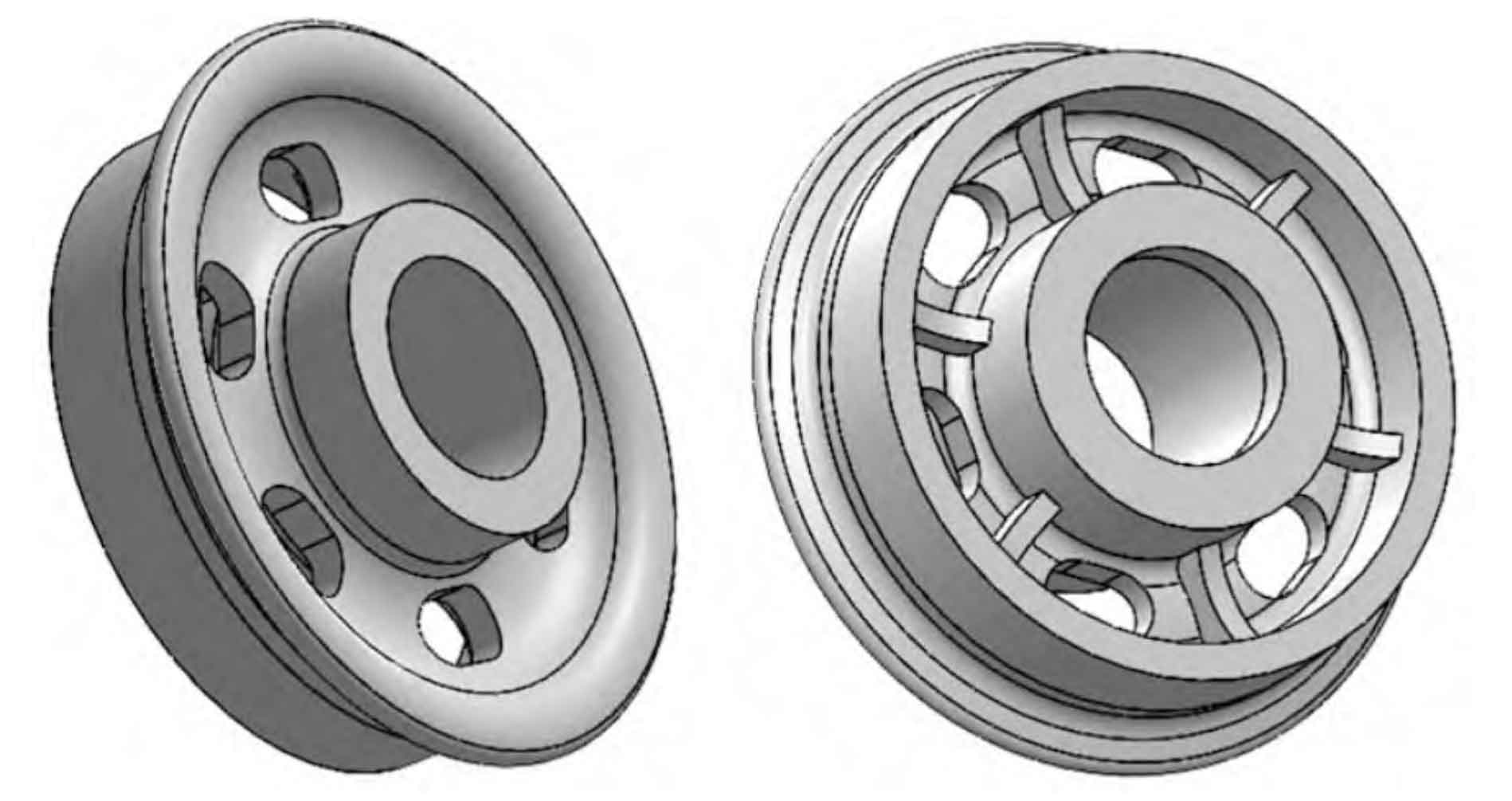

Figure 1 is a three-dimensional part drawing of the wheel of a mining flat car, with an outline dimension of 353 mm × 403 mm × 152 mm, the wall thickness of the outer ring of the wheel is 20 mm, and the wall thickness of the wheel hub is 36 mm. The initial scheme of wheel casting gating system is established by using SolidWorks 3D software, as shown in Figure 2. The wheel is made of zg50mn2 with a mass of 59.2 kg and is made of sand mold gravity casting.

2. Design of wheel gating system

As the wheel is a small steel casting, which is the wheel of mining flat car, and the load demand is large, casting defects such as shrinkage porosity and shrinkage cavity are not allowed during pouring and solidification. Because cast steel has the characteristics of high melting point, poor fluidity, large shrinkage and easy oxidation, it is required that the molten metal be filled quickly and smoothly [8]. According to the design principle of the parting surface, the parting surface is placed on the wheel split, which is also a processing surface, and the casting is easy to take the mold. This casting is a small and medium-sized steel casting produced in large quantities. A semi closed gating system is adopted to strengthen the slag retaining capacity, and the process scheme of one box for one piece is adopted. According to the structural characteristics of wheel casting, a reasonable gating system can make it fill mold smoothly and reduce the possibility of scouring the mold cavity and generating entrainment. The cross-sectional ratio of each sprue is: Σ a straight: Σ a cross: Σ a inner =1.2:0.8:1. The total cross-sectional area of the ingate is calculated to be 19.4 cm2. Because there are three designed ingates, the cross-sectional area of one ingate is 6.5 cm2, and the total cross-sectional areas of the sprue and the cross-sectional area of the ingate are 23.3 cm2 and 15.5 cm2 respectively. The determined sizes of each sprue are shown in Figure 3.