Riser refers to the structure artificially set in the pouring and riser system to store metal liquid. In the pouring process of sand castings, the riser mainly plays a role in compensating the shrinkage cavity and porosity that may occur in the liquid shrinkage and solidification shrinkage stages in the molding process of castings. In addition, it also plays the role of exhaust, slag collection and guiding mold filling. The main goal of riser design in sand casting is to obtain castings without shrinkage defects and pursue the maximum production benefit of castings.

Specific to the riser design of the sand casting coupling parts shown in the figure, although there are porous and middle sand core structures at the inner side of the thick section of the sand casting coupling parts, these structures increase the surface area of this part, but due to the small diameter of these holes, the volume of the sand core is small. During the pouring of liquid metal, it is quickly heated to the temperature close to the liquid metal, and the heat dissipation effect of this part in the way of heat transfer is relatively small, which weakens its chilling effect. Therefore, the solidification speed of this part is less than that of the outside. The hot joint in the thick section should move to the center of the circle along the internal center line of the thick section of the casting, so as to delay the solidification time near the internal sand core. The thin-walled part of the casting is placed below, the modulus is very small and solidification is preferred. Therefore, when calculating the modulus, the simplified thick section structure is regarded as an expanded long rod body. Modulus of this part MC = 2.30cm. According to the size of MC, the riser modulus is Mr = 1.3cm, and the riser neck modulus Mn = 0.67mr = 0.87cm.

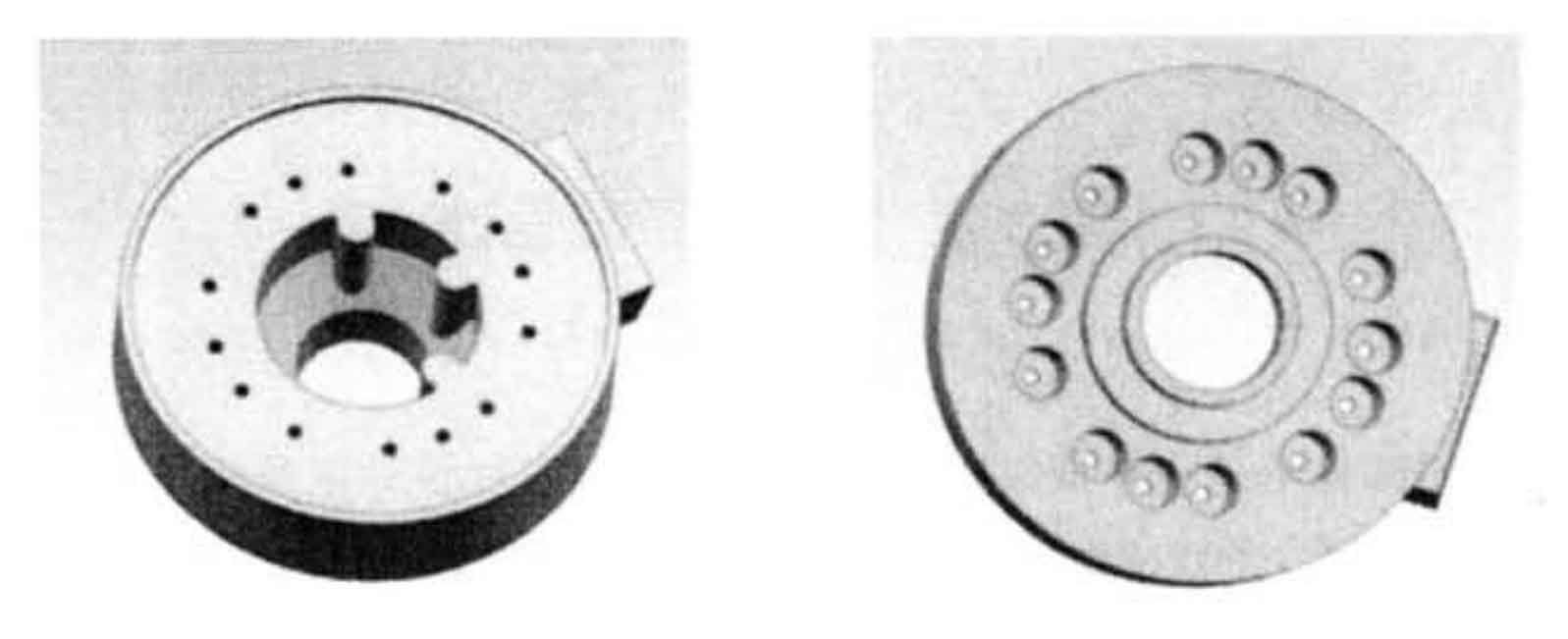

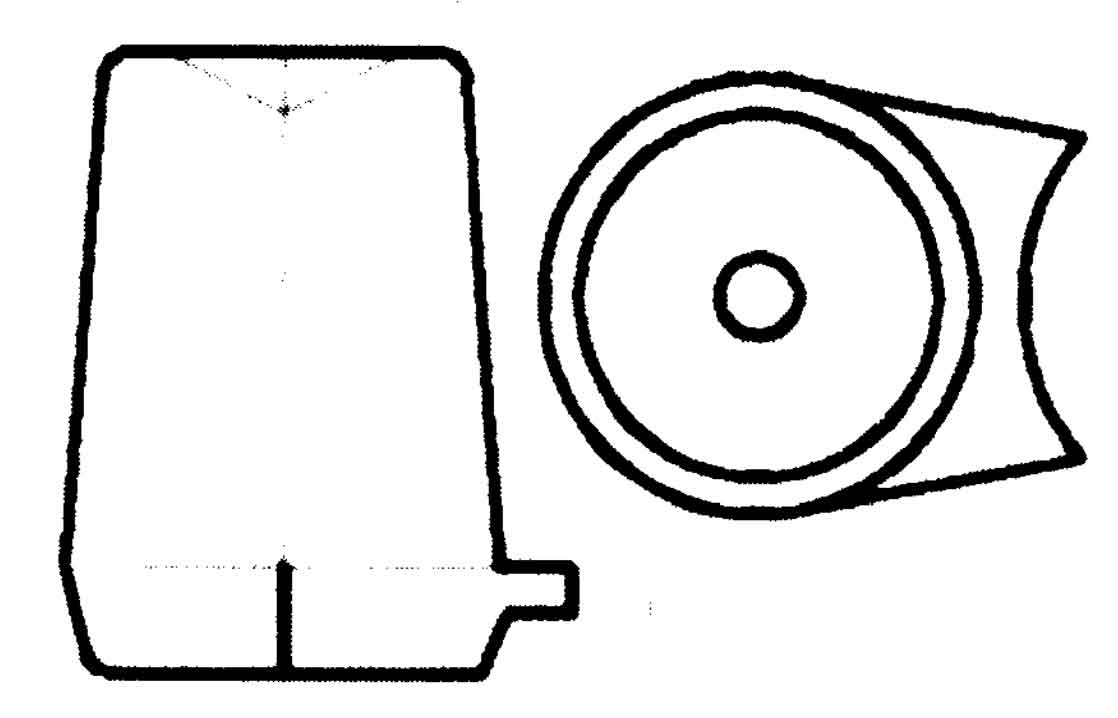

Check the casting manual, select the blank holder riser as the side riser, the number is four, and the size is shown in Figure 1. The interface between riser and casting cavity shall be treated according to the shape of casting cavity. The upper plane of the interface between the riser and the casting cavity is coplanar with the upper plane of the casting cavity. The effective height of riser is 85mm. After calculation, the weight of the four risers is approximately 8.40kg. According to the maximum wall thickness of sand casting and the pouring strategy of “high temperature fast pouring”, the pouring temperature of molten metal is tentatively set at 1460 ° C. the specific riser size of sand casting is shown in Figure 2.