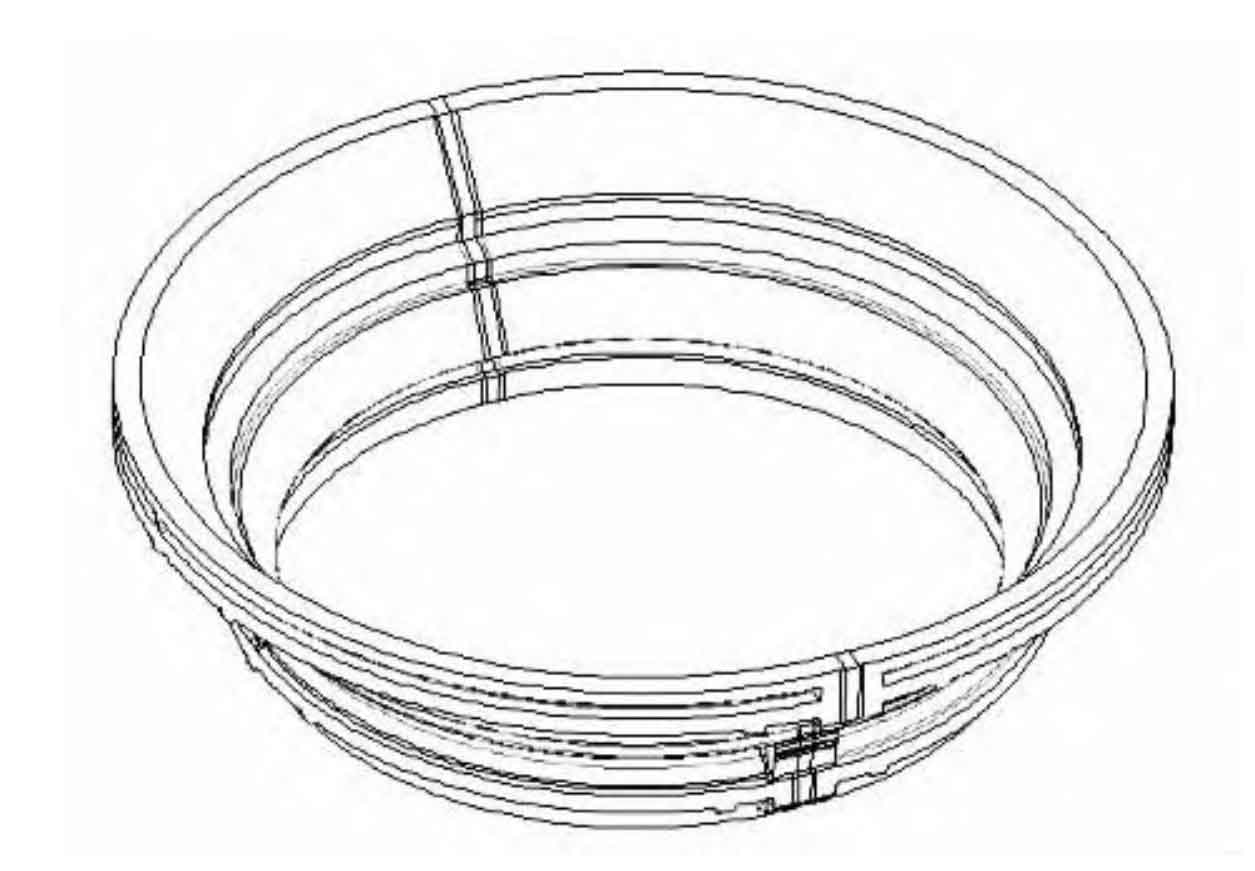

Taking a hydro-environment product as an example, the overall dimension of the product body φ 4 600 mm × 1 100 mm, the shape and structure are shown in Figure 1. These products are characterized by large structure contour and small wall thickness. In order to adapt to the large contour shape of the casting, the traditional sand casting of such products adopts the internal and external integral quicksand molding to obtain the semi-finished cavity required before casting, as shown in Figure 2.

Compared with the weight of sand castings, the use weight of resin sand inside and outside of such products will be more than 13 times of the weight of sand castings. Each product sand is a one-time semi-finished product and cannot be recycled. The cost of resin sand accounts for 20% of the total production cost of sand castings, resulting in lower profits of steel castings. At the same time, due to the excessive thickness of resin sand, it is difficult to exhaust the gas after internal resin combustion during pouring, which is easy to cause defects such as pores and slag inclusion in sand castings.

Therefore, it is necessary to make a tool for reducing the amount of sand used for general steel castings, which can be disassembled, assembled and recycled for use. The purpose is to reduce the amount of resin sand used in sand casting of steel castings in the existing technology, reduce the casting cost of steel castings, and reduce the appearance defects of products.