To obtain a dense casting, the sprue cup should be poured as soon as possible and always filled during the pouring process, otherwise the rest of the gating system will not match the calculated performance. A good sprue cup has the following characteristics:

(1) It is easy to start pouring, liquid metal will not splash even at a higher initial pouring speed, and it needs a faster speed to fill the sprue cup as soon as possible.

(2) The liquid metal should be transported to other parts of the gating system in order to obtain the metal static pressure as soon as possible, which is very important to determine the size of the gating system.

(3) The size shall be such that after it is filled, impurities can float to the upper surface during the casting process.

(3) The size shall be such that after it is filled, impurities can float to the upper surface during the casting process.

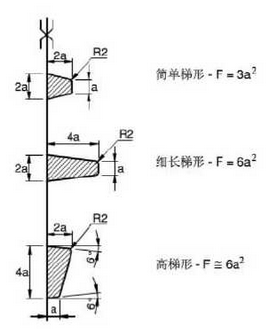

The sprue is all the channels leading liquid metal from the gate cup to the inner gate. The runner has many other functions besides guiding metal, such as preventing slag, oxide, sand and gas from entering the cavity. There are three kinds of sectional area of runner, which are simple trapezoid, slender trapezoid and high trapezoid. The corresponding cross-sectional area calculation formula is as follows:

As the density of impurities is less than that of molten iron, it will float up after filling the horizontal runner and adhere to the upper surface of the runner. Therefore, the horizontal runner should choose the slender runner with wide liquid level and large upper surface.