Sand casting is indeed a unique combination of art and science, where skilled craftsmanship meets the principles of materials engineering. This process involves transforming molten metal into intricate and functional masterpieces. Let’s explore the artistry and scientific aspects that come together in the art and science of sand casting:

Pattern Making and Mold Design:

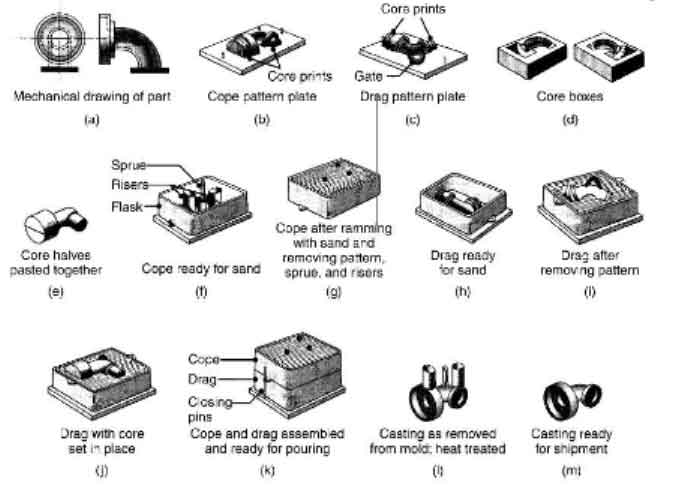

Pattern making is a crucial artistic skill in sand casting. Pattern makers meticulously craft the patterns, often using wood, plastic, or metal, to create replicas of the desired parts. They consider factors such as shrinkage, draft angles, and parting lines, ensuring the patterns facilitate the creation of high-quality molds.

Mold design is both an art and a science. It involves determining the mold geometry, gating system, and risers to facilitate proper filling, minimize defects, and achieve dimensional accuracy. Mold designers must understand the flow of molten metal and account for solidification behavior to create molds that produce sound castings.

Molding and Core Making:

Molding sand preparation is a critical aspect of sand casting. Molders skillfully mix the sand with binders and additives to achieve the desired properties, such as strength, permeability, and collapsibility. They compact the sand around the pattern, creating the mold cavity with intricate details and features.

Core making adds another layer of artistry and science. Core makers create sand cores that form internal cavities or complex shapes within the casting. They carefully design and produce cores that can withstand the molten metal’s thermal and mechanical stresses, ensuring the integrity of the final castings.

Pouring and Solidification:

Pouring molten metal into the mold requires skill and precision. The molten metal must flow smoothly through the gating system, filling the mold cavity without turbulence or entrapment of air. Proper pouring techniques, such as controlling the metal’s temperature, flow rate, and direction, are critical for achieving sound castings.

The solidification process is where the science of materials engineering plays a significant role. Understanding the cooling rates, solidification behavior of the metal, and controlling the rate of solidification helps ensure proper grain structure, mechanical properties, and freedom from defects in the castings.

Finishing and Post-Casting Processes:

The artistry in sand casting continues during the finishing and post-casting stages. Craftsmen employ various techniques to remove the casting from the mold, clean the surface, and remove any excess sand or imperfections. Finishing processes, such as grinding, polishing, and machining, are applied to achieve the desired surface finish and dimensional accuracy.

Artistic craftsmanship also comes into play when applying surface coatings, such as painting, plating, or heat treatment, to enhance the aesthetics or functional properties of the castings. These post-casting processes require attention to detail and skill to achieve the desired results.

Quality Control and Continuous Improvement:

The art and science of sand casting converge in the realm of quality control and continuous improvement. Foundries employ rigorous inspection techniques, such as dimensional measurement, non-destructive testing, and metallurgical analysis, to ensure the castings meet the required specifications and standards.

Foundries embrace the principles of continuous improvement, leveraging scientific methods, data analysis, and feedback loops to refine their processes, optimize parameters, and reduce defects. Skilled technicians, engineers, and metallurgists collaborate to troubleshoot issues, implement corrective actions, and drive the evolution of sand casting techniques.

Conclusion:

Sand casting is a captivating blend of artistry and scientific principles. From pattern making and mold design to pouring, solidification, finishing, and quality control, the craftsmanship and technical expertise of individuals involved are essential in creating metal masterpieces. By combining their artistic flair with the knowledge of materials science and engineering, sand casting professionals continue to push the boundaries of what can be achieved through this time-honored casting method.