Spheroidal graphite cast iron, also known as ductile iron, is a type of cast iron characterized by its spherical graphite inclusions, which give it enhanced mechanical properties compared to traditional gray cast iron. Here’s a comprehensive guide covering its properties and applications:

Properties

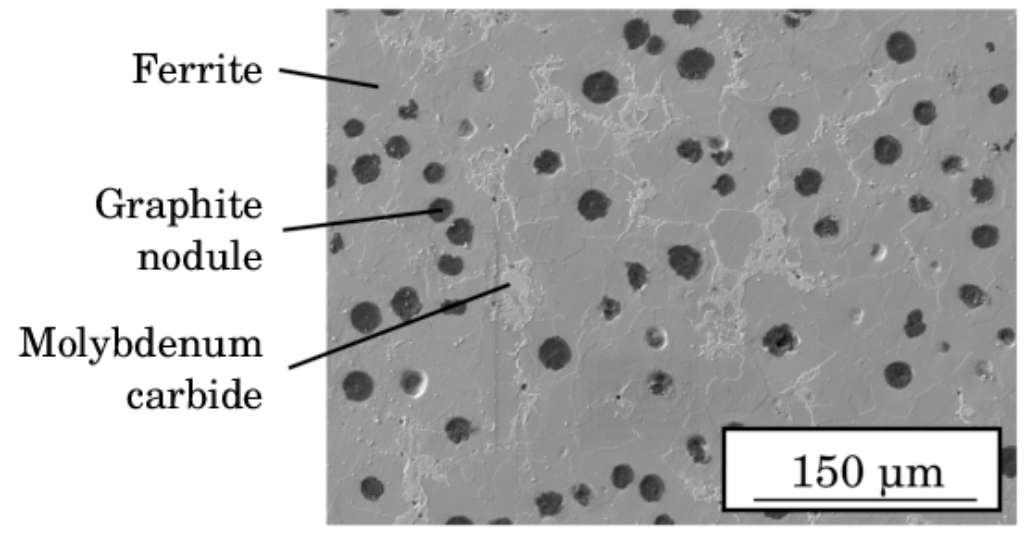

- Graphite Structure: Unlike the flake graphite structure in gray cast iron, spheroidal graphite cast iron has a spherical graphite structure. This structure imparts higher tensile strength, ductility, and toughness.

- Tensile Strength: Typically, ductile iron has a tensile strength ranging from 400 to 1000 MPa, which is considerably higher than gray cast iron.

- Elongation: It exhibits a significantly higher elongation at break (around 2-18%), making it more ductile and less brittle.

- Impact Resistance: The spheroidal graphite nodules enhance the impact resistance, especially at low temperatures.

- Wear Resistance: It offers good wear resistance due to the graphite acting as a lubricant.

- Corrosion Resistance: While ductile iron is more corrosion-resistant than gray cast iron, it’s less resistant compared to steel.

- Heat Treatment: Ductile iron responds well to heat treatment, which can further improve its mechanical properties.

Applications

- Piping and Pipe Fittings: Due to its strength and durability, ductile iron is commonly used for pipes and pipe fittings, especially for water and sewage lines.

- Automotive Components: Its strength and fatigue resistance make it ideal for manufacturing automotive parts like crankshafts, gears, and wheel hubs.

- Machinery: Used in the manufacturing of gears, sprockets, and other heavy machinery components.

- Structural and Architectural Applications: Its strength and aesthetic appeal make it suitable for use in architectural elements like street furniture, lamp posts, and bridge components.

- Agricultural Machinery: Utilized in the manufacture of tractors and agricultural machinery parts due to its strength and wear resistance.

- Wind Turbines: Components like hubs and gearbox housings in wind turbines are often made from ductile iron.

Machining and Fabrication

- Ductile iron can be machined more easily than ordinary cast iron.

- Welding ductile iron requires specific techniques and precautions due to its unique graphite structure.

Future Trends

- Advancements in metallurgy may lead to the development of ductile iron with even better properties.

- Its use in green energy and sustainability projects, like wind turbines, is expected to increase.

Conclusion

Spheroidal graphite cast iron’s combination of strength, ductility, and toughness makes it an excellent material for a wide range of applications, from heavy industry to everyday infrastructure. Its versatility and mechanical properties ensure its continued relevance in various engineering and manufacturing domains.