Steel casting has been a cornerstone of various industries for centuries, and its future is filled with promising trends and innovative advancements. This article explores the emerging trends and transformative innovations that are shaping the future of steel casting, including advancements in materials, technologies, sustainability, automation, and customization.

- Advanced Materials for Enhanced Performance: The future of steel casting is marked by the development and utilization of advanced materials. High-performance alloys, including stainless steels, heat-resistant alloys, and corrosion-resistant grades, are being engineered to meet the evolving demands of industries. These materials offer superior strength, durability, and specialized properties, enabling the production of components with enhanced performance in challenging environments.

- Digitalization and Industry 4.0 Integration: The integration of digitalization and Industry 4.0 technologies is revolutionizing the steel casting industry. Advanced simulation software, digital twin models, and real-time monitoring systems are being employed to optimize casting processes, predict defects, and enhance quality control. Additionally, the implementation of robotics, automation, and artificial intelligence (AI) is streamlining production, improving efficiency, and reducing human error.

- Sustainability and Environmental Responsibility: Sustainability is a driving force in the future of steel casting. Manufacturers are adopting environmentally friendly practices, such as energy-efficient melting processes, waste reduction, and recycling initiatives. The use of eco-friendly binders and molding materials, along with the promotion of circular economy principles, ensures that steel casting aligns with sustainable development goals.

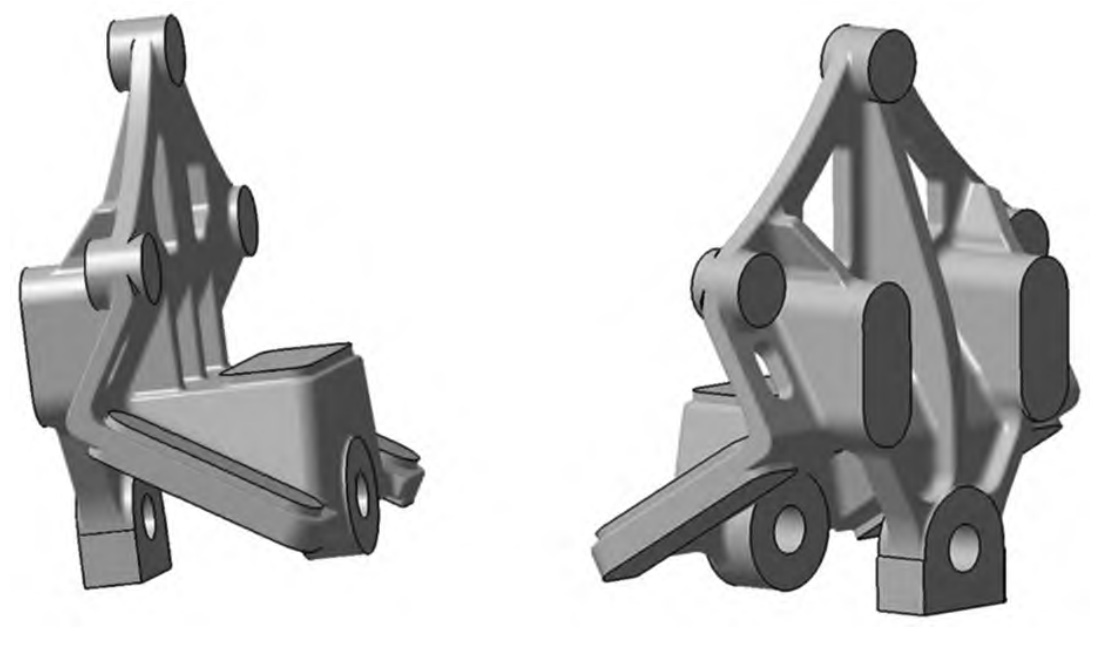

- Customization and Complex Geometries: Advancements in casting techniques and tooling technologies are enabling the production of highly complex and customized steel castings. Innovations such as 3D printing, investment casting, and lost foam casting allow for intricate geometries, improved dimensional accuracy, and reduced lead times. This trend opens up new possibilities for industries seeking unique, lightweight, and high-performance components.

- Quality Assurance and Non-Destructive Testing: The future of steel casting emphasizes rigorous quality assurance and non-destructive testing methods. Advanced inspection techniques, including X-ray, ultrasonic testing, and laser scanning, ensure the detection of defects and enhance the reliability of castings. Real-time monitoring and data analytics enable predictive maintenance and proactive quality control measures.

- Collaboration and Industry Partnerships: Collaboration and partnerships between steel casting manufacturers, research institutions, and end-users are fostering innovation and driving industry growth. The exchange of knowledge, expertise, and resources accelerates the development of new casting techniques, materials, and applications. Collaboration also facilitates the implementation of industry-wide standards, ensuring consistent quality and promoting market acceptance.

The future of steel casting is filled with exciting trends and transformative innovations that will shape various industries. From advanced materials and digitalization to sustainability initiatives, customization capabilities, and quality assurance measures, the industry is evolving to meet the demands of modern manufacturing. By embracing these trends and fostering collaboration, the steel casting industry is poised for continued growth, improved performance, and expanded applications in a wide range of sectors.