Spheroidal Graphite Cast Iron is type of cast iron that offers superior mechanical properties due to its unique microstructure. The spheroidal, or nodular, form of graphite in this iron gives it excellent strength, ductility, and toughness, distinguishing it from traditional gray cast iron. This article delves into the metallurgy of Spheroidal Graphite Cast Iron, focusing on its composition and microstructure analysis.

Composition of Spheroidal Graphite Cast Iron

The composition of Spheroidal Graphite Cast Iron is carefully controlled to achieve its desirable properties. The primary elements in its composition include iron, carbon, silicon, manganese, magnesium, and trace amounts of other elements.

Key Elements and Their Roles

- Iron (Fe): The base metal that forms the majority of the composition.

- Carbon (C): Present in the range of 3.0-4.0%, carbon forms graphite nodules, which are crucial for the ductility and toughness of the iron.

- Silicon (Si): Ranges from 1.8-2.8%. Silicon promotes graphite formation and improves the casting process.

- Manganese (Mn): Typically present in 0.1-1.0%, manganese helps to control the matrix structure by preventing the formation of iron carbides.

- Magnesium (Mg): Added in small amounts (0.03-0.05%) to transform graphite flakes into spheroidal nodules.

- Other Elements: Trace elements such as copper, nickel, molybdenum, and cerium may be added to enhance specific properties.

Table 1: Typical Composition of Spheroidal Graphite Cast Iron

| Element | Composition (wt%) |

|---|---|

| Iron (Fe) | Balance |

| Carbon (C) | 3.0 – 4.0 |

| Silicon (Si) | 1.8 – 2.8 |

| Manganese (Mn) | 0.1 – 1.0 |

| Magnesium (Mg) | 0.03 – 0.05 |

| Other Elements | Trace Amounts |

Role of Alloying Elements

- Copper and Nickel: Improve strength and toughness.

- Molybdenum: Enhances high-temperature strength and corrosion resistance.

- Cerium: Acts as a nodulizing agent to ensure the formation of spherical graphite nodules.

List 1: Alloying Elements and Their Effects

- Copper and Nickel: Increase strength and toughness.

- Molybdenum: Enhances high-temperature strength and corrosion resistance.

- Cerium: Ensures the formation of spherical graphite nodules.

Microstructure of Spheroidal Graphite Cast Iron

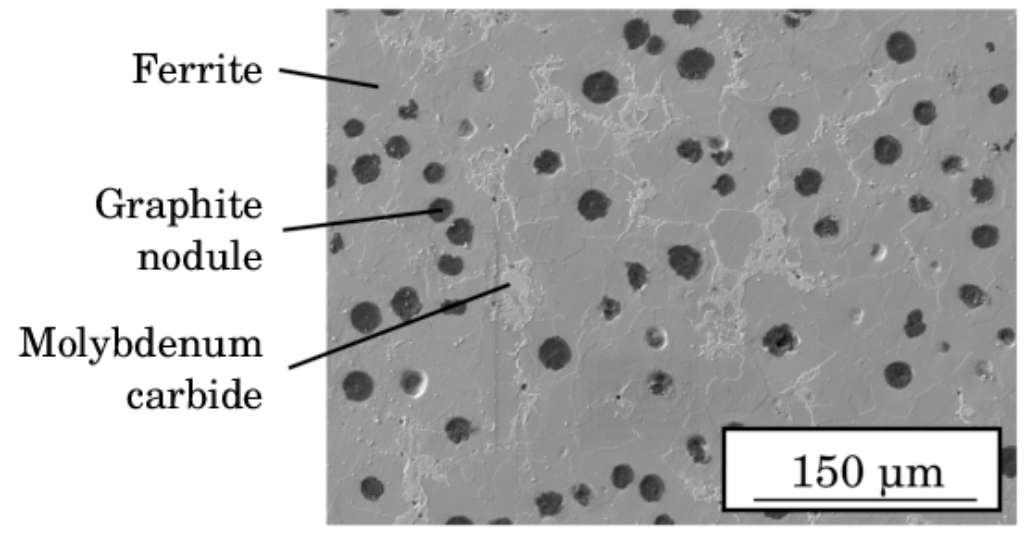

The microstructure of Spheroidal Graphite Cast Iron is characterized by spherical graphite nodules embedded in a metallic matrix. This unique microstructure is what imparts the superior mechanical properties to the iron.

Graphite Nodules

Graphite in Spheroidal Graphite Cast Iron appears as spheroidal nodules rather than flakes. This shape reduces the stress concentration points within the iron, significantly enhancing its strength and ductility.

Formation of Graphite Nodules

- Magnesium Addition: The addition of magnesium transforms the graphite from a flake form to a spheroidal form.

- Inoculation: Inoculants like ferrosilicon are added to the molten iron to promote the formation of graphite nodules.

Table 2: Formation of Graphite Nodules

| Process | Description |

|---|---|

| Magnesium Addition | Transforms graphite from flake to spheroidal form |

| Inoculation | Promotes the formation of graphite nodules |

Metallic Matrix

The matrix in which the graphite nodules are embedded can vary depending on the heat treatment and alloying elements. The matrix phases primarily include ferrite, pearlite, and austenite.

Matrix Phases

- Ferrite: Soft and ductile phase, enhancing the ductility of the iron.

- Pearlite: Combination of ferrite and cementite, providing a balance of strength and ductility.

- Austenite: Can be retained at room temperature with certain alloying additions, providing high strength and toughness.

List 2: Matrix Phases

- Ferrite: Enhances ductility.

- Pearlite: Balances strength and ductility.

- Austenite: Provides high strength and toughness.

Microstructural Analysis

Microstructural analysis involves examining the morphology and distribution of graphite nodules and the matrix phases. This analysis helps in understanding the properties and performance of Spheroidal Graphite Cast Iron.

Techniques for Microstructural Analysis

- Optical Microscopy: Used to observe the graphite nodules and matrix phases.

- Scanning Electron Microscopy (SEM): Provides detailed images of the microstructure, revealing finer details.

- Energy Dispersive X-ray Spectroscopy (EDS): Used alongside SEM to analyze the elemental composition of the phases.

Table 3: Techniques for Microstructural Analysis

| Technique | Description |

|---|---|

| Optical Microscopy | Observes graphite nodules and matrix phases |

| Scanning Electron Microscopy (SEM) | Provides detailed microstructural images |

| Energy Dispersive X-ray Spectroscopy (EDS) | Analyzes elemental composition |

Enhancing Mechanical Properties Through Microstructure Control

Control over the microstructure of Spheroidal Graphite Cast Iron is crucial for enhancing its mechanical properties. Various techniques are employed to achieve the desired microstructure.

Heat Treatment Processes

Heat treatment processes such as annealing, normalizing, and austempering are used to control the microstructure and improve the mechanical properties.

Heat Treatment Techniques

- Annealing: Reduces hardness and improves ductility by transforming the matrix to ferrite.

- Normalizing: Refines the grain structure, enhancing strength and toughness.

- Austempering: Produces a bainitic microstructure, significantly improving strength and toughness.

Table 4: Heat Treatment Techniques

| Technique | Effect on Microstructure and Properties |

|---|---|

| Annealing | Reduces hardness, improves ductility (ferritic matrix) |

| Normalizing | Refines grain structure, enhances strength and toughness (pearlitic matrix) |

| Austempering | Produces bainitic microstructure, improves strength and toughness |

Alloying and Inoculation

Optimizing the composition through alloying and inoculation is essential for controlling the microstructure and enhancing properties.

Techniques for Optimization

- Alloying: Adjusting the levels of alloying elements like copper, nickel, and molybdenum to achieve the desired matrix structure.

- Inoculation: Using effective inoculants to ensure the formation of uniform and spheroidal graphite nodules.

List 3: Techniques for Optimization

- Alloying: Adjust levels of elements like copper, nickel, and molybdenum.

- Inoculation: Use effective inoculants for uniform graphite nodule formation.

Applications of Spheroidal Graphite Cast Iron

The enhanced mechanical properties of Spheroidal Graphite Cast Iron make it suitable for a wide range of applications across various industries.

Automotive Industry

- Engine Components: Crankshafts, camshafts, and cylinder heads benefit from the high strength and fatigue resistance.

- Suspension Parts: Control arms and suspension knuckles utilize the excellent ductility and impact resistance.

Aerospace Industry

- Landing Gear: Used in landing gear components for its strength and toughness.

- Engine Parts: Suitable for turbine housings and other high-temperature components due to its superior properties.

Industrial Machinery

- Pumps and Valves: Ideal for components subjected to high wear and pressure.

- Heavy Machinery: Gears, bearings, and other parts that require high strength and durability.

Table 5: Applications of Spheroidal Graphite Cast Iron

| Industry | Applications |

|---|---|

| Automotive | Engine components, suspension parts |

| Aerospace | Landing gear, engine parts |

| Industrial Machinery | Pumps, valves, gears, bearings |

Conclusion

Understanding the metallurgy of Spheroidal Graphite Cast Iron, including its composition and microstructure, is essential for leveraging its superior mechanical properties and performance. Through precise control of alloying elements, inoculation, and heat treatment processes, sand casting manufacturers can optimize the microstructure to meet specific application requirements. The advancements in production techniques and the detailed analysis of microstructure have significantly enhanced the capabilities of Spheroidal Graphite Cast Iron, making it a preferred material for a wide range of demanding applications. As research and development continue to drive innovations in this field, the potential for further improvements in the properties and applications of Spheroidal Graphite Cast Iron remains substantial.