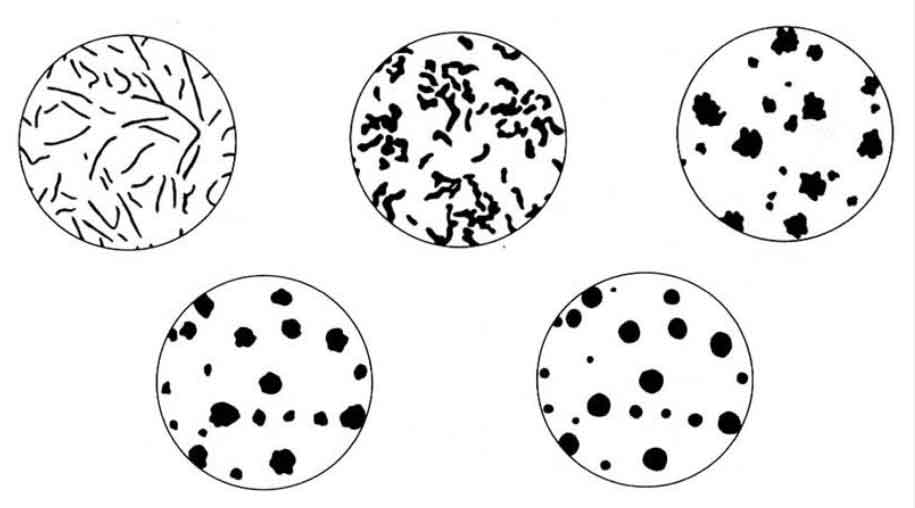

Spheroidal graphite iron, also known as ductile iron or nodular cast iron, is a type of cast iron that exhibits improved mechanical properties compared to traditional gray iron. It owes its superior properties to the presence of spheroidal graphite nodules instead of flake graphite.

The mechanical properties of spheroidal graphite iron can vary depending on the specific composition and heat treatment, but generally, it possesses the following characteristics:

- Tensile Strength: Spheroidal graphite iron has high tensile strength, typically ranging from 400 to 700 megapascals (MPa). This strength is comparable to low and medium carbon steels.

- Yield Strength: The yield strength of Spheroidal graphite iron is usually in the range of 250 to 500 MPa. Yield strength refers to the stress at which the material starts to deform plastically.

- Ductility: Spheroidal graphite iron exhibits good ductility, allowing it to undergo significant deformation before failure. It typically has an elongation at fracture of 10% or more, making it suitable for applications where deformation or impact resistance is required.

- Impact Resistance: Spheroidal graphite iron possesses excellent impact resistance due to its nodular graphite structure. The nodules act as stress concentrators, absorbing and dispersing energy during impact, thereby preventing the propagation of cracks.

- Fatigue Strength: Spheroidal graphite iron has a high fatigue strength, making it resistant to cyclic loading and repetitive stress. It can withstand millions of load cycles without failure, making it suitable for components subjected to dynamic or cyclic loading.

- Hardness: The hardness of Spheroidal graphite iron can vary depending on the matrix structure and heat treatment. Typically, it has a hardness range of 170 to 250 Brinell hardness (HB), which is higher than that of gray iron.

- Thermal Conductivity: Spheroidal graphite iron exhibits good thermal conductivity, allowing it to dissipate heat efficiently. This property is beneficial in applications where heat transfer is critical, such as engine blocks or heat exchangers.

- Machinability: Spheroidal graphite iron is generally considered to have good machinability. It can be easily machined using conventional methods, such as turning, milling, and drilling, although it may require appropriate cutting tools and techniques due to its hardness.

It’s important to note that these mechanical properties are general characteristics, and the actual values may vary depending on the specific alloying elements, microstructure, and heat treatment applied to the Spheroidal graphite iron. Furthermore, the mechanical properties can be further improved through specific alloying additions or heat treatments tailored to meet the requirements of a particular application.