To achieve accuracy and quality in sand casting parts, several key factors should be considered and implemented throughout the process. Here are some essential steps and guidelines:

- Design and pattern making:

- Begin with a well-designed part, ensuring that it can be successfully cast using sand casting.

- Create a high-quality pattern with precise dimensions, smooth surfaces, and appropriate allowances for shrinkage and machining.

- Sand preparation:

- Use high-quality sand with the right grain size and properties for the specific casting requirements.

- Control the sand mixture composition and moisture content to achieve optimal mold quality and strength.

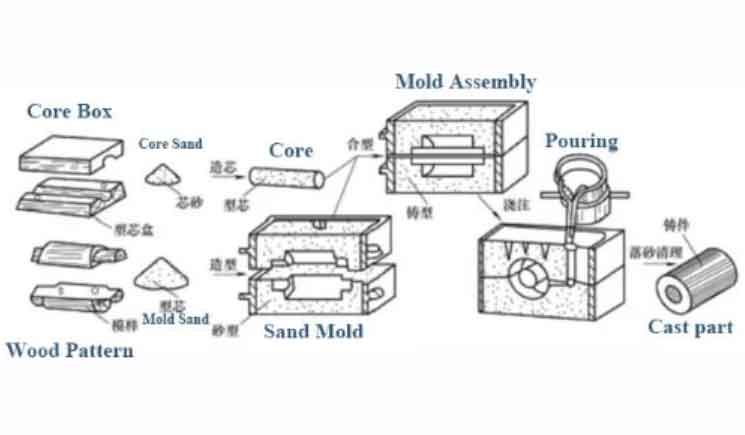

- Molding:

- Ensure proper compaction of the sand around the pattern to maintain accurate dimensions and minimize defects like voids or sand inclusions.

- Use proper gating and riser design to ensure even filling of the mold and promote directional solidification.

- Melting and pouring:

- Use high-quality metal alloys with the correct composition and properties for the intended application.

- Employ proper melting and alloying techniques to achieve a consistent and controlled metal temperature.

- Control the pouring process to avoid turbulence, minimize air entrapment, and ensure uniform metal flow into the mold.

- Cooling and solidification:

- Allow sufficient cooling time to ensure complete solidification of the metal before removing the casting.

- Implement proper cooling techniques to minimize thermal stresses and prevent distortion or cracking.

- Finishing and post-processing:

- Remove the casting from the mold carefully to prevent damage.

- Perform necessary post-processing operations like trimming, grinding, and machining to achieve the desired final dimensions and surface finish.

- Inspect the casting for any defects or imperfections and rectify or scrap as necessary.

- Quality control and testing:

- Implement a robust quality control system to monitor and control each stage of the sand casting process.

- Perform inspections, dimensional measurements, and non-destructive testing (such as X-ray or ultrasound) to detect and rectify any defects or deviations from specifications.

- Continuous improvement:

- Analyze any defects or quality issues that arise during the sand casting process.

- Identify root causes and implement corrective actions to improve future production runs.

- Regularly review and optimize the process parameters, materials, and equipment to enhance accuracy and quality.

By following these steps and continuously improving the sand casting process, you can achieve higher accuracy and quality in the production of sand casting parts. It is also important to stay updated on the latest advancements in sand casting technology and techniques to incorporate best practices and innovations into your process.