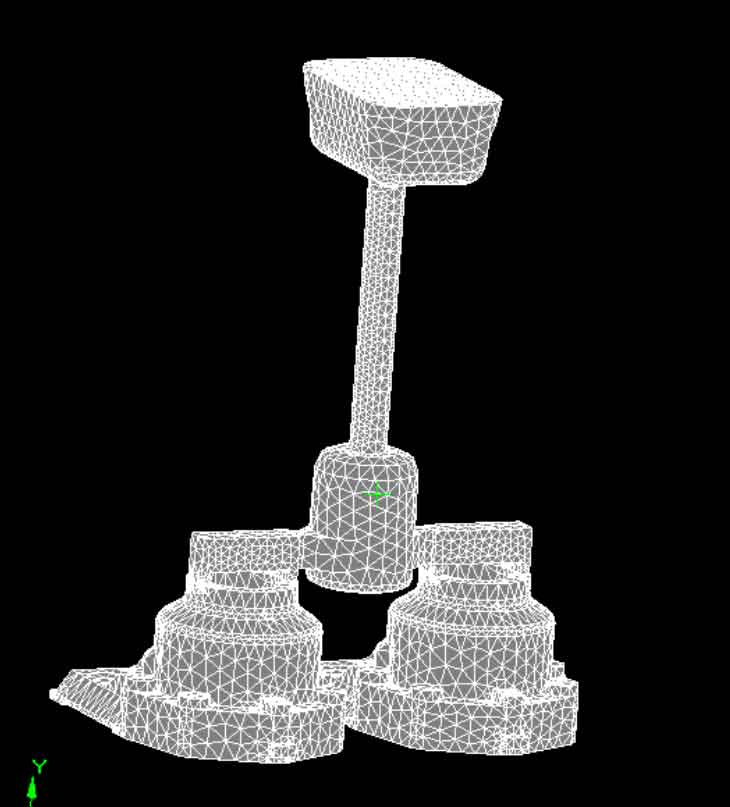

Tetrahedral mesh is still used in meshing. After meshing, the whole model package has 163266 nodes and 884220 elements. The finite element model of lost foam casting is shown in the figure.

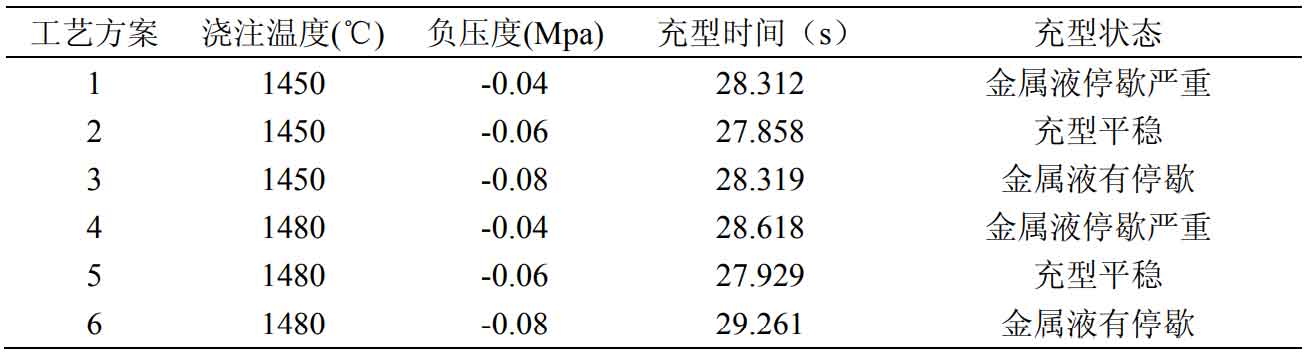

In lost foam casting, pouring temperature and vacuum degree have an important impact on the mold filling, solidification process and quality of lost foam casting. In order to select the appropriate pouring temperature and vacuum degree, six sets of process schemes are formulated for simulation, as shown in the table.

It can be seen that under certain conditions of pattern density, pouring temperature and other influencing factors of lost foam casting, with the increase of vacuum degree, the filling time first decreases and then increases. When the true void is -0.06mpa, the filling time is the shortest. At the same time, it can be found that under low and high vacuum, the liquid metal filling is unstable, and even there is a short filling pause.

In scheme 3 and scheme 5, the mold filling is relatively stable, and the mold filling time is basically the same. However, in the simulation process of scheme 3, it is found that some of the lost foam casting parts begin to solidify during the mold filling process. Through comparison, it is finally considered that scheme 5 with pouring temperature of 1480 ℃ and vacuum degree of -0.06mpa is a more reasonable process scheme.