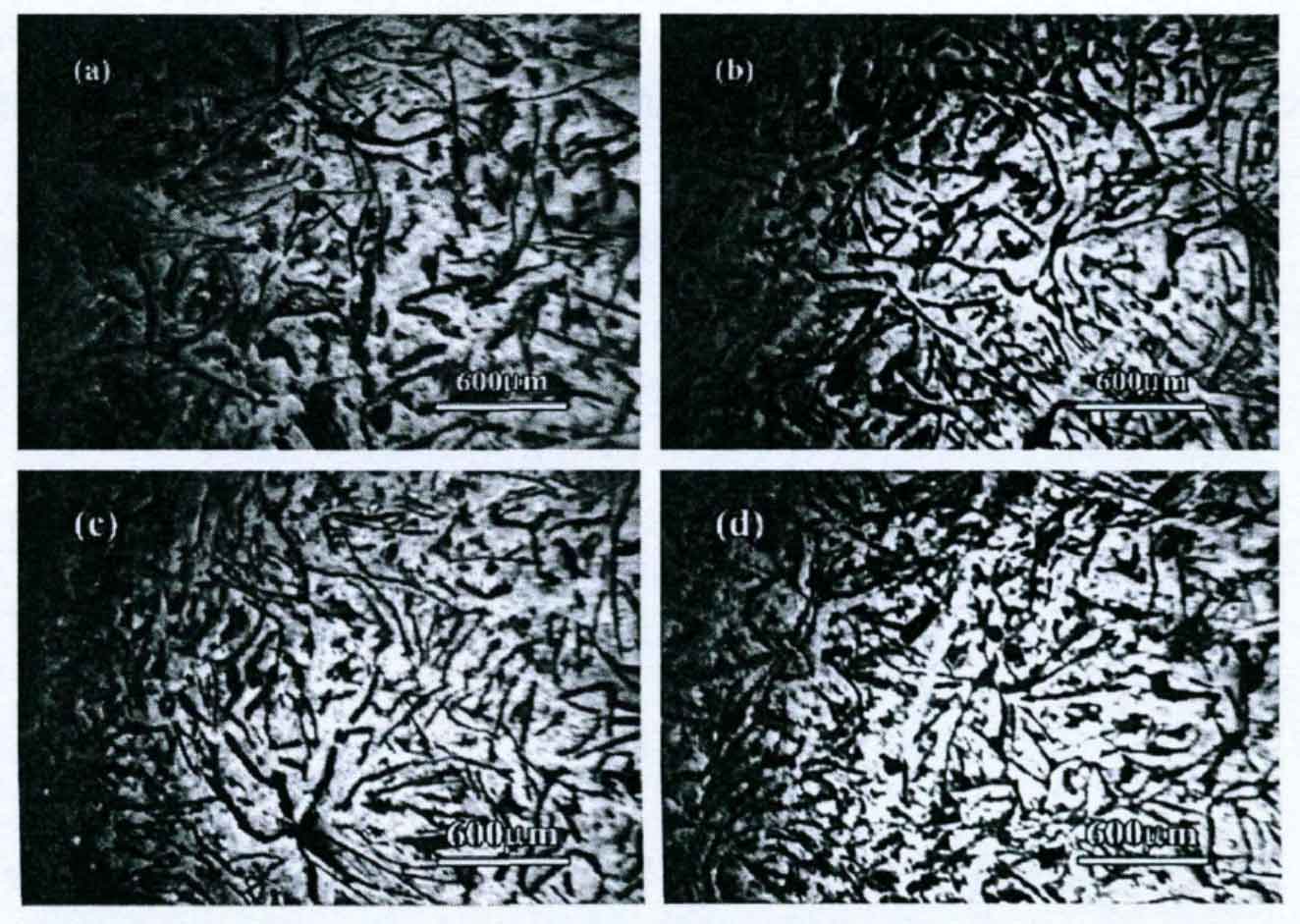

In the process of vibration lost foam casting of gray cast iron, the vibration promotes the convection of metal solution, resulting in the fracture, fragmentation and proliferation of austenite dendrite arms, which increases the number of austenite grains in gray cast iron and refines the austenite dendrite grains.

The results show that vibration can refine the primary austenite dendrites of lost foam casting gray cast iron. The main reason is that the solidification process of lost foam casting gray cast iron is affected by various forces, including the exciting force caused by vibration, the resistance of metal bodies to the movement of austenite dendrites. When the force is greater than the strength limit of austenite dendrites, the austenite dendrites break Crushing and increment increase the number of crystal nuclei in the metal, refine the austenite dendrites, and reduce the grain size of austenite. Based on the analysis results, a mechanical model of austenite dendrite fracture is established.

In order to build the mechanical model of primary austenite fracture, the following assumptions are made for the metal melt:

① The branch arm of austenite branch is regarded as a simple cylinder;

② The growth direction of austenite branch arm is horizontal;

③ The metal solution vibrates synchronously with the shaking table, and the vibration frequency and amplitude are the same;

④ In the solidification process, except for vibration, there is no other factor causing the flow of metal solution, and the solute and temperature distribution in the metal solution are uniform;

⑤ During solidification, the viscosity coefficient of metal solution is regarded as a constant;

⑥ The resistance of metal to austenite dendrite movement is uniformly distributed on the austenite dendrite arm;

⑦ The effect of gravity on austenite dendrites is neglected.