Gray cast iron is a type of cast iron that has a microstructure characterized by graphite flakes in a matrix of ferrite and/or pearlite. The graphite gives gray cast iron its distinctive gray color when fractured. This form of cast iron is one of the most commonly used materials in engineering due to its versatility, cost-effectiveness, and unique properties. Here’s a deeper look into gray cast iron, including its properties, applications, and advantages:

Properties

- Graphite Flakes: The presence of graphite flakes within its structure provides several key properties, such as improved machinability and vibration damping.

- Compressive Strength: While gray cast iron has good compressive strength, it is relatively weaker in tension due to the presence of graphite flakes, which act as stress concentration points.

- Wear Resistance: It offers moderate wear resistance, which can be enhanced depending on the matrix structure and the presence of alloying elements.

- Thermal Conductivity: High thermal conductivity compared to other ferrous metals, making it suitable for applications involving heat dissipation.

- Damping Capacity: Excellent ability to dampen vibrations, which is why it is often used for machinery bases and automotive components.

Applications

Gray cast iron is used in a wide range of applications, some of which include:

- Automotive Industry: Engine blocks, cylinder heads, brake discs, and gearboxes are commonly made from gray cast iron due to its machinability, damping properties, and thermal conductivity.

- Machinery and Equipment: Base frames, machine beds, and other components that require excellent vibration damping and stability are often manufactured from gray cast iron.

- Pipes and Fittings: Due to its good fluidity, castability, and corrosion resistance, gray cast iron is used for water pipes, sewer pipes, and fittings.

- Cookware: The thermal properties of gray cast iron make it an excellent material for cookware, such as frying pans and Dutch ovens.

Advantages

- Machinability: The presence of graphite in gray cast iron acts as a lubricant, reducing wear on cutting tools and making it easier to machine than many other metals.

- Cost-Effective: Gray cast iron is relatively inexpensive to produce, especially for parts that can be made in a single casting, reducing the need for extensive machining or fabrication.

- Vibration Damping: The ability to dampen vibrations makes gray cast iron ideal for applications where reducing noise and vibration is important.

- Thermal Conductivity: Its high thermal conductivity makes it suitable for applications that require rapid heat dissipation.

- Castability: The fluidity of the molten iron allows it to be cast into complex shapes, which can reduce the need for additional machining or assembly.

Despite its advantages, gray cast iron’s brittleness and lower tensile strength compared to other cast irons or steels limit its use in applications requiring ductility or impact resistance. However, its unique combination of properties ensures that it remains a popular choice for many engineering applications.

Chapter 1: The Basic Characteristics of Gray Cast Iron

Gray cast iron is a type of iron-carbon alloy that possesses distinct characteristics, microstructure, and mechanical properties, making it suitable for various industrial applications. Here’s an overview of its basic characteristics and their effects on performance and applications:

1. Alloy Composition: Gray cast iron is primarily composed of iron and carbon, along with small amounts of other elements that influence its properties. The typical alloy composition includes:

- Carbon (C): 2.5% – 4.0%

- Silicon (Si): 1.0% – 3.0%

- Manganese (Mn): 0.5% – 1.0%

- Sulfur (S): 0.02% – 0.25%

- Phosphorus (P): 0.1% – 1.0%

2. Microstructure: The distinctive feature of gray cast iron is its graphite microstructure, which appears as flakes or lamellae within the iron matrix. This microstructure gives the iron its characteristic gray color and affects its properties.

3. Mechanical Properties: The presence of graphite in gray cast iron significantly influences its mechanical properties:

- Strength: Gray cast iron has relatively low tensile strength and hardness compared to other cast irons, due to the presence of graphite flakes that act as stress concentrators.

- Brittleness: The presence of graphite makes gray cast iron brittle, which means it tends to fracture under relatively low impact loads.

- Damping Capacity: Gray cast iron has excellent damping capacity, making it suitable for applications where vibration dampening is crucial.

- Wear Resistance: The graphite flakes act as solid lubricants, providing good wear resistance and self-lubrication properties.

- Machinability: Gray cast iron is relatively easy to machine due to the presence of graphite, which forms chips during machining, reducing tool wear.

4. Applications: Gray cast iron’s characteristics make it suitable for a range of applications:

- Automotive Industry: Engine blocks, cylinder heads, brake discs, and other components benefit from gray cast iron’s excellent damping and wear resistance.

- Machinery and Equipment: Gears, pulleys, and heavy-duty machinery parts use gray cast iron for its self-lubricating properties and machinability.

- Pipes and Fittings: Gray cast iron is used for water pipes and sewer systems due to its corrosion resistance and longevity.

- Cookware: The ability to retain and distribute heat makes gray cast iron a popular choice for cookware like frying pans and dutch ovens.

- Construction: Gray cast iron is used for decorative elements, such as ornamental fences and lampposts.

5. Performance and Applications: The characteristics of gray cast iron influence its performance and applications in the following ways:

- Damping Capacity: Gray cast iron’s excellent damping capacity is valuable in applications where noise reduction and vibration absorption are critical, such as engine components and machinery.

- Wear Resistance: Self-lubricating properties and wear resistance make it suitable for components that experience sliding and abrasive wear, like gears and brake discs.

- Machinability: Gray cast iron’s machinability allows for efficient production of intricate components, reducing manufacturing costs.

- Brittleness: While gray cast iron’s brittleness can be a disadvantage in applications requiring high impact resistance, its properties can be optimized for specific uses through alloy modifications and heat treatments.

In summary, gray cast iron’s alloy composition, microstructure, and mechanical properties, particularly its graphite flakes, determine its unique characteristics. These characteristics are leveraged for various applications where wear resistance, damping capacity, and machinability are essential.

Chapter 2: Fluidity of Gray Cast Iron

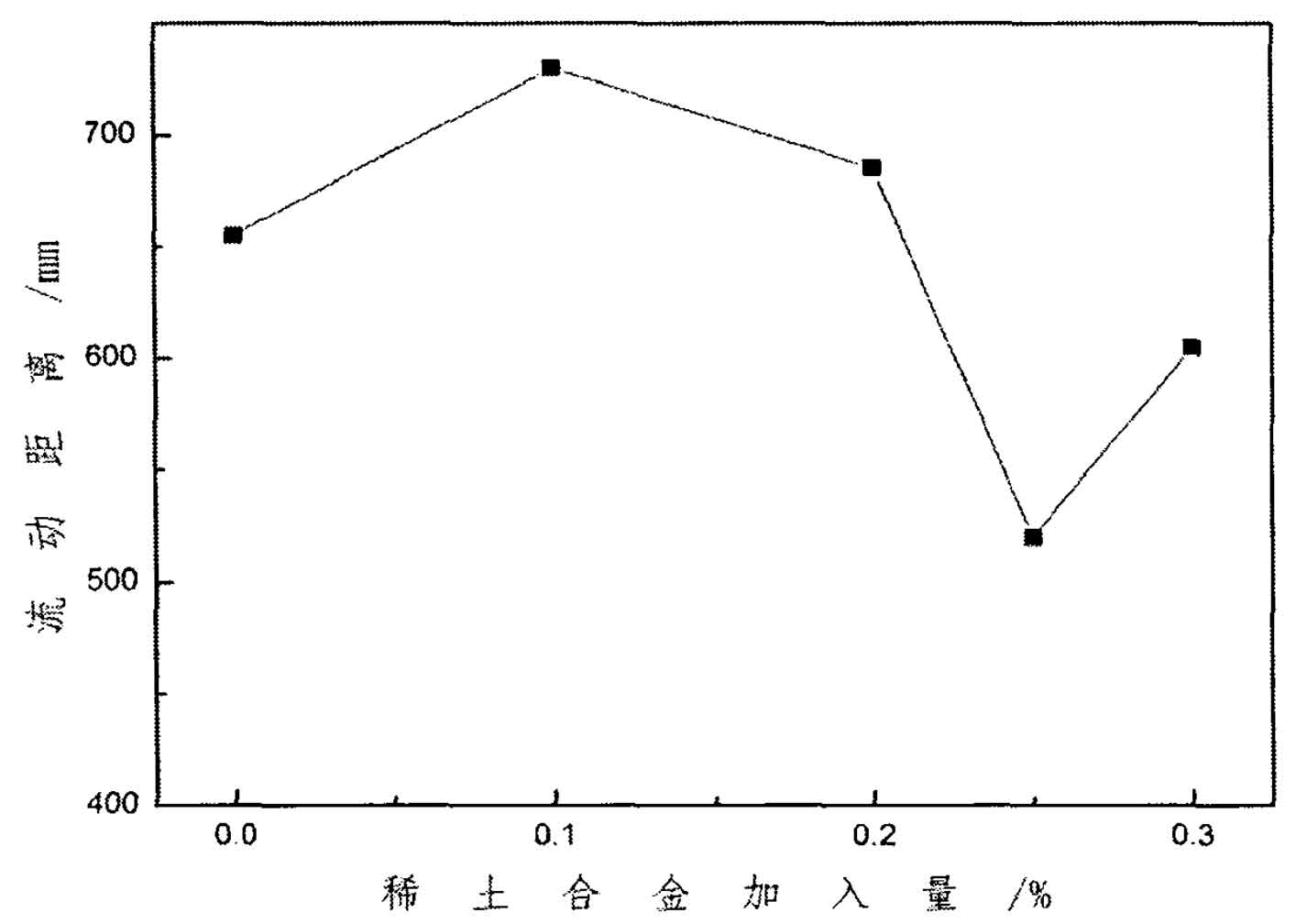

Fluidity is affected by many factors, the most important of which is pouring temperature and chemical composition. The discharging temperature of molten iron is controlled between 1500-1550 ° C and the pouring temperature is controlled between 1400-1450 ° C. the single helix wet type sample is used to test the fluidity of low-carbon equivalent gray cast iron. According to the experimental data in the table, the test results are between 520-730mm, indicating that the fluidity of low-carbon equivalent gray cast iron is poor, but the fluidity after rare earth alloy modification is better than that before modification.

| Furnace No. | 1 | 2 | 3 | 4 | 5 |

| RE/% | 0 | 0.1 | 0.2 | 0.25 | 0.3 |

| Result / mm | 655 | 730 | 685 | 520 | 605 |

Low carbon equivalent gray cast iron has poor fluidity, which is not conducive to the floating of gas and impurities, resulting in pores and impurities during solidification, resulting in casting defects. Within a certain range, the addition of rare earth alloy in the smelting process can effectively improve the flow performance of low-carbon equivalent gray cast iron. It can be seen from the figure that the flow performance of low-carbon equivalent gray cast iron first increases and then decreases with the increase of the amount of rare earth alloy. When the total amount of rare earth is 0.1%, the flow performance of molten iron is the best; When the content of rare earth alloy is 0.25%, there is a huge turning point, and the flow performance of molten iron increases instead.

The pouring temperature and burden composition of each sample are the same, so only rare earth affects the fluidity of gray cast iron. Rare earth has the functions of desulfurization, deoxidation, dephosphorization and neutralization of some impurity elements, which greatly reduces the content of non-metallic inclusions and harmful gases in molten iron and helps to improve the fluidity of gray cast iron. Therefore, the fluidity of molten iron is improved during the initial addition of rare earth; However, at the same time, rare earth has the tendency of supercooling. Excessive addition of rare earth increases the supercooling tendency of molten iron, accelerates the cooling speed, and worsens the flow performance; When the content of rare earth is 0.25%, the fluidity of molten iron is improved again; At this time, vermicular graphite and spherical graphite appear in low-carbon equivalent gray cast iron, the eutectic range increases, and the time of gray cast iron in liquid state increases. Therefore, the fluidity of low-carbon equivalent gray cast iron increases again.

Chapter 3: The Main Alloying Elements of Gray Cast Iron

The main alloying elements in gray cast iron are carbon (C), silicon (Si), phosphorus (P), and sulfur (S). These elements play a crucial role in determining the microstructure and properties of the castings. Here’s how each element affects the properties of gray cast iron:

1. Carbon (C): Carbon is a primary alloying element in gray cast iron and has a significant impact on its properties. The graphite microstructure in gray cast iron is formed due to the presence of carbon. The effects of carbon include:

- Graphite Formation: Carbon precipitates in the form of graphite flakes within the iron matrix, imparting the characteristic gray color and providing self-lubricating and wear-resistant properties.

- Brittleness: Higher carbon content leads to an increase in the size and amount of graphite flakes, which reduces the overall strength and makes the cast iron more brittle.

- Thermal Conductivity: Carbon helps maintain good thermal conductivity in gray cast iron, making it suitable for applications requiring heat transfer.

2. Silicon (Si): Silicon is another important element in gray cast iron and affects its microstructure and mechanical properties. The effects of silicon include:

- Graphite Morphology: Silicon promotes the formation of graphite flakes with a distinct shape and size, influencing the mechanical properties of the iron.

- Fluidity: Silicon improves the fluidity of the molten iron during casting, allowing for better mold filling and reduced susceptibility to defects.

- Graphitization: Silicon promotes the formation of stable graphite structures during solidification, enhancing the overall mechanical properties.

3. Phosphorus (P): Phosphorus is a common impurity found in gray cast iron, and its content is typically controlled to avoid adverse effects on properties. The effects of phosphorus include:

- Graphite Degradation: Excessive phosphorus can lead to the formation of brittle iron-phosphide compounds, which weaken the cast iron and reduce its impact resistance.

- Fluidity: Small amounts of phosphorus can improve fluidity during casting, aiding in mold filling.

4. Sulfur (S): Sulfur is another impurity that can impact gray cast iron’s properties, primarily negatively. The effects of sulfur include:

- Graphite Formation: Sulfur tends to form iron sulfides, which can act as nuclei for undesired eutectic structures, potentially weakening the cast iron.

- Machinability: While sulfur can aid in machining by promoting chip formation, excessive sulfur can lead to brittleness and reduced mechanical properties.

The alloying elements carbon, silicon, phosphorus, and sulfur have distinct effects on the microstructure and properties of gray cast iron. Carbon primarily contributes to the graphite microstructure and its associated properties, while silicon enhances fluidity and promotes favorable graphite formation. Phosphorus and sulfur, although considered impurities, can have both positive and negative impacts on cast iron properties, depending on their concentration and how they interact with other elements. Balancing these alloying elements is crucial to achieving the desired properties in gray cast iron for specific applications.

Chapter 4: Understand the Microstructure of Gray Cast Iron

The microstructure of gray cast iron is characterized by a unique arrangement of graphite flakes within a matrix phase. This microstructure imparts distinct properties to the material, and the arrangement of graphite and the matrix phase has a significant impact on its performance. Let’s delve deeper into the microstructure and its effects:

Microstructure Components:

- Graphite: The graphite in gray cast iron is present in the form of flakes or lamellae. These flakes are dispersed within the iron matrix. Graphite provides several beneficial properties, including self-lubrication, excellent damping capacity, and thermal conductivity.

- Matrix Phase: The matrix phase consists of the iron and other alloying elements. It surrounds the graphite flakes and provides the mechanical strength of the material. The matrix phase’s composition and structure influence the overall mechanical properties of the gray cast iron.

Impact of Microstructure on Performance: The arrangement and characteristics of the graphite flakes and the matrix phase significantly influence the performance of gray cast iron:

- Flake Size and Distribution:

- Effects: The size and distribution of graphite flakes affect the material’s strength, hardness, and brittleness. Larger flakes can act as stress concentrators, reducing tensile strength and increasing brittleness.

- Performance Impact: Castings with finer and more uniformly distributed graphite flakes tend to exhibit improved mechanical properties, such as higher tensile strength, reduced brittleness, and improved impact resistance.

- Matrix Composition and Structure:

- Effects: The composition of the matrix phase, including alloying elements like silicon and carbon, affects the overall mechanical properties and microstructural stability.

- Performance Impact: Proper control of matrix composition, especially silicon content, can optimize the formation of a desirable graphite morphology and enhance mechanical properties.

- Graphite Morphology:

- Effects: The shape and size of graphite flakes influence properties such as thermal conductivity, wear resistance, and machinability. Different morphologies include Type A (fine flakes), Type B (coarser flakes), and Type C (intermediate flakes).

- Performance Impact: Type A graphite morphology is associated with improved mechanical properties and higher tensile strength due to reduced stress concentration effects. Type C flakes offer a balance between properties.

- Matrix-Microstructure Interaction:

- Effects: The interaction between the matrix and graphite affects stress distribution, crack propagation, and overall material behavior.

- Performance Impact: A well-balanced interaction between the matrix and graphite can lead to improved toughness, impact resistance, and thermal stability.

- Heat Treatment and Solidification Rate:

- Effects: Heat treatment and solidification rate during casting influence the size and distribution of graphite flakes and the matrix structure.

- Performance Impact: Proper heat treatment and controlled solidification rate can help achieve the desired microstructure for specific applications, enhancing mechanical properties.

The microstructure of gray cast iron, characterized by the arrangement of graphite flakes and the matrix phase, has a profound impact on its mechanical properties and performance. By controlling factors such as flake size, distribution, matrix composition, and solidification conditions, manufacturers can tailor the microstructure to achieve optimal properties for various applications, ensuring a balance between strength, brittleness, wear resistance, and other crucial characteristics.

Chapter 5: The Mechanical Properties of Different Types of Gray Cast Iron

The mechanical properties of gray cast iron can vary significantly based on factors such as the graphite morphology, matrix composition, and heat treatment. Different types of gray cast iron are classified based on their graphite morphology, primarily into three types: Type A, Type B, and Type C. Each type exhibits distinct mechanical properties, including hardness and strength. Here’s an overview of the properties of these types:

1. Type A Gray Cast Iron:

- Graphite Morphology: Fine and uniformly distributed graphite flakes.

- Mechanical Properties:

- Hardness: Relatively higher hardness compared to other types due to reduced stress concentration effects from fine graphite flakes.

- Tensile Strength: Exhibits higher tensile strength compared to other types due to reduced brittleness associated with fine flakes.

- Impact Resistance: Improved impact resistance due to the fine graphite morphology.

- Machinability: Generally better machinability compared to coarser graphite types.

2. Type B Gray Cast Iron:

- Graphite Morphology: Coarser graphite flakes compared to Type A.

- Mechanical Properties:

- Hardness: Moderate hardness, typically lower than Type A.

- Tensile Strength: Tensile strength is generally lower due to the larger graphite flakes, which act as stress concentrators.

- Impact Resistance: Impact resistance is lower compared to Type A due to larger graphite flakes.

- Machinability: Machinability is somewhat reduced compared to Type A due to the coarser flakes.

3. Type C Gray Cast Iron:

- Graphite Morphology: Intermediate graphite flakes, offering a balance between fine and coarse flakes.

- Mechanical Properties:

- Hardness: Hardness is moderate, falling between Types A and B.

- Tensile Strength: Tensile strength is also intermediate, benefiting from a balanced graphite morphology.

- Impact Resistance: Impact resistance is improved compared to Type B but might be slightly lower than Type A.

- Machinability: Machinability is generally better than Type B but might not be as good as Type A.

It’s important to note that the mechanical properties of gray cast iron can also be influenced by other factors, such as the composition of the matrix phase, heat treatment, and casting conditions. Additionally, alloying elements like silicon, carbon, and trace elements can impact the overall mechanical behavior of gray cast iron.

In practical applications, the choice of gray cast iron type depends on the specific requirements of the component. Type A gray cast iron might be preferred for applications where higher strength, hardness, and impact resistance are crucial. Type B might find use in applications where damping and vibration absorption are more important. Type C can be suitable for applications that require a balance between different mechanical properties.

Understanding the mechanical properties of different types of gray cast iron helps engineers and manufacturers select the appropriate type for specific applications, ensuring optimal performance and durability.

Chapter 6: The Advantages and Disadvantages of Gray Cast Iron in Different Applications

Gray cast iron offers a range of advantages and disadvantages that make it suitable for certain applications while limiting its use in others. Here’s a breakdown of these aspects across various applications:

Advantages of Gray Cast Iron:

- Automotive Industry:

- Advantages: Gray cast iron’s good damping capacity and wear resistance make it ideal for components like engine blocks, cylinder heads, and brake discs, which require noise reduction, vibration absorption, and heat dissipation.

- Machinery and Equipment:

- Advantages: Gray cast iron’s self-lubricating properties and machinability are beneficial for producing gears, pulleys, and heavy-duty machinery parts that need wear resistance and ease of machining.

- Pipes and Fittings:

- Advantages: Gray cast iron’s corrosion resistance and longevity make it a suitable material for water pipes and sewer systems, providing stability and reducing maintenance.

- Cookware:

- Advantages: Gray cast iron’s ability to retain and distribute heat evenly makes it popular for cookware like frying pans and dutch ovens.

- Construction:

- Advantages: Gray cast iron’s strength and durability are useful for decorative elements in construction, such as ornamental fences and lampposts.

Disadvantages of Gray Cast Iron:

- Brittleness:

- Disadvantages: Gray cast iron’s inherent brittleness makes it unsuitable for applications requiring high impact resistance, as it tends to fracture rather than deform under stress.

- Limited Tensile Strength:

- Disadvantages: Gray cast iron’s low tensile strength can be a limitation in applications where high mechanical loading or tension is involved.

- Heavy Weight:

- Disadvantages: Gray cast iron’s density and weight can be a disadvantage in applications where lightweight materials are desired to reduce overall product weight.

- Limited Weldability:

- Disadvantages: Gray cast iron’s graphite flakes and brittleness can hinder its weldability and may require specialized techniques.

- Poor Machinability (in some cases):

- Disadvantages: While gray cast iron is generally considered easy to machine, the presence of coarse graphite flakes in certain types might lead to tool wear and reduced machinability.

- Thermal Expansion:

- Disadvantages: Gray cast iron’s relatively high coefficient of thermal expansion can lead to thermal stresses and distortion in applications exposed to varying temperature conditions.

- Cracking during Cooling:

- Disadvantages: The cooling process during casting can lead to internal stress and potential cracking in thick sections of gray cast iron components.

Gray cast iron’s advantages lie in its damping capacity, wear resistance, self-lubrication, and thermal properties, making it suitable for applications where these characteristics are valuable. However, its brittleness, limited tensile strength, and other drawbacks restrict its use in applications demanding high impact resistance, lightweight structures, or precise machinability. Engineers and designers must carefully assess the material’s pros and cons to select the right type of gray cast iron for specific applications.

Chapter 7: Heat Treatment Methods for Gray Cast Iron

Heat treatment methods can be employed to modify the properties and microstructure of gray cast iron to meet specific application requirements. While some traditional heat treatments like annealing and normalizing are less common for cast iron compared to other materials, they can still be utilized. Quenching and tempering are more widely applied to achieve desired mechanical properties. Here’s an overview of these methods and their effects:

1. Annealing:

- Method: Annealing involves heating gray cast iron to a temperature below its eutectic temperature and then slowly cooling it in a furnace. This process reduces internal stresses and refines the microstructure.

- Effects: Annealing can soften the material, improve machinability, and relieve internal stresses. It tends to produce a fine pearlite matrix.

- Applications: Annealing might be applied to reduce brittleness and improve machinability, but it’s less commonly used for gray cast iron.

2. Normalizing:

- Method: Normalizing involves heating gray cast iron to a temperature above its eutectic temperature and then cooling it in still air. This process produces a finer pearlite microstructure.

- Effects: Normalizing can enhance the mechanical properties and improve uniformity in the microstructure.

- Applications: Normalizing is less commonly applied to gray cast iron compared to other heat treatment methods.

3. Quenching and Tempering:

- Method: Quenching involves rapid cooling (usually in water or oil) from an elevated temperature to achieve high hardness. Tempering follows quenching and involves reheating the material to a lower temperature to reduce brittleness while maintaining some hardness.

- Effects: Quenching produces a hard and brittle structure, while tempering balances hardness with improved toughness.

- Applications: Quenching and tempering can be used to achieve specific hardness levels and desired combinations of strength and toughness in components like wear-resistant parts.

4. Austempering:

- Method: Austempering involves quenching gray cast iron to a temperature just above the eutectoid temperature and holding it at that temperature for a specific time before cooling. This process produces a bainitic microstructure.

- Effects: Austempering can improve the toughness and impact resistance of gray cast iron while maintaining some hardness.

- Applications: Austempering is used to enhance the properties of specific components requiring a combination of strength and toughness.

It’s important to note that gray cast iron’s unique microstructure, primarily consisting of graphite flakes, influences its heat treatment behavior. The graphite can act as a thermal insulator, affecting heat transfer during the process. Additionally, different types of gray cast iron (Type A, B, C) may respond differently to heat treatment due to variations in graphite morphology.

The selection of a suitable heat treatment method for gray cast iron depends on the desired properties and the specific application. Engineers should consider the graphite morphology, cooling rates, and other factors to achieve the desired balance of properties while managing the challenges posed by the material’s microstructure.

Chapter 8: The Casting Technology of Grey Cast Iron

The casting process of gray cast iron involves various methods, including sand casting and lost foam casting. Each method has its own advantages and limitations that can impact the quality of the resulting castings.

1. Sand Casting:

Sand casting is a widely used method for casting gray cast iron. The process involves creating a mold from compacted sand that is shaped to match the desired component. Here’s an overview of the sand casting process and its impact on casting quality:

Process Steps:

- Pattern Creation: A pattern, which is a replica of the final component, is created. It can be made of wood, plastic, or metal.

- Mold Preparation: Sand is packed around the pattern to create a mold cavity. The mold is usually made in two halves, the cope and the drag.

- Core Placement: If the component has internal features, cores made from sand or other materials are placed within the mold to create voids.

- Melting and Pouring: Gray cast iron is melted in a furnace, and the molten metal is poured into the mold through a sprue.

- Solidification: The molten metal cools and solidifies, taking the shape of the mold cavity.

- Mold Removal: Once the metal has solidified, the mold is broken apart, and the casting is removed.

Impact on Casting Quality:

- Advantages: Sand casting is versatile, cost-effective, and suitable for producing complex shapes and larger components.

- Challenges: The quality of the casting can be influenced by factors such as mold density, venting, and the properties of the sand used. Sand-related defects like porosity and sand inclusions can occur.

2. Lost Foam Casting:

Lost foam casting (also known as evaporative pattern casting) is another method used for gray cast iron casting. In this process, a foam pattern is used, which vaporizes when the molten metal is poured, creating the mold cavity. Here’s an overview of the lost foam casting process and its impact on casting quality:

Process Steps:

- Pattern Creation: A foam pattern is created using a mold or CNC machining.

- Cluster Assembly: Multiple foam patterns are attached to a gating system to form a cluster.

- Cluster Coating: The foam cluster is coated with a refractory material to create a shell around the pattern.

- Pattern Removal: The coated cluster is heated, causing the foam to vaporize and leaving behind a shell mold.

- Pouring: Molten gray cast iron is poured into the shell mold.

- Solidification: The metal cools and solidifies, taking the shape of the mold.

- Shell Removal: Once the casting has solidified, the shell is removed by shaking or sandblasting.

Impact on Casting Quality:

- Advantages: Lost foam casting allows for intricate designs and near-net shape castings. It eliminates the need for pattern removal and reduces the risk of pattern-related defects.

- Challenges: The process requires precise control over the shell coating and the casting process to prevent defects like gas porosity and mold erosion. Proper venting is crucial to allow gases to escape during vaporization of the foam pattern.

The casting process of gray cast iron, whether through sand casting or lost foam casting, has a significant impact on the quality of the castings produced. Both methods offer advantages and challenges that need to be carefully managed to achieve the desired casting quality, dimensional accuracy, and mechanical properties. The choice of casting method depends on factors such as component complexity, required tolerances, and production volume.

Chapter 9: The Application of Grey Cast Iron Castings

Gray cast iron castings are widely used in various industries due to their unique properties and advantages. Some of the prominent fields where gray cast iron castings find extensive application include:

- Automotive Industry:

- Engine Components: Gray cast iron is commonly used for engine blocks and cylinder heads due to its excellent damping capacity, wear resistance, and thermal conductivity.

- Brake Discs and Drums: Its wear resistance and self-lubricating properties make it suitable for brake components that endure friction and heat.

- Exhaust Manifolds: Gray cast iron’s ability to withstand high temperatures and corrosion resistance make it a good choice for exhaust components.

- Machinery and Equipment:

- Gears and Gearboxes: Gray cast iron’s self-lubricating properties and wear resistance make it suitable for gear applications.

- Pulleys and Flywheels: Its ability to store and dissipate heat makes it useful for applications requiring thermal stability.

- Machine Tool Components: Its machinability makes it a preferred choice for producing machine tool components that require precision machining.

- Engineering Machinery:

- Construction Equipment: Components like frames, housings, and parts of construction machinery benefit from gray cast iron’s strength and durability.

- Agricultural Machinery: Cast iron components offer ruggedness and durability required for agricultural equipment.

- Pipes and Fittings:

- Water and Sewer Systems: Gray cast iron pipes and fittings are known for their corrosion resistance and long service life in water distribution and sewage systems.

- Cookware and Household Items:

- Cookware: Gray cast iron is used to manufacture frying pans, dutch ovens, and other cookware due to its even heat distribution and retention properties.

- Ornamental Items: Decorative elements like fences, railings, and lampposts can be made from gray cast iron for their aesthetic appeal and durability.

- Marine Industry:

- Marine Engine Components: Gray cast iron’s properties make it suitable for marine engine components that require durability, wear resistance, and thermal stability.

- Hydraulic and Pneumatic Systems:

- Valve Bodies and Housings: Gray cast iron’s strength and resistance to deformation under pressure make it suitable for valve components in hydraulic and pneumatic systems.

- Railway Industry:

- Railway Brake Components: Brake discs and drums made from gray cast iron provide effective braking and wear resistance in railway systems.

- Industrial Machinery:

- Heavy Industrial Equipment: Components that require strength, wear resistance, and thermal stability are often made from gray cast iron.

While gray cast iron has widespread applications, its usage has evolved with advancements in materials and manufacturing techniques. Engineers and designers carefully consider the specific requirements of each application and select the appropriate materials, including gray cast iron, to ensure optimal performance and durability.

Chapter 10: The Quality Control of Gray Cast Iron Castings

Quality control for gray cast iron castings involves various methods to ensure that the products meet desired specifications and standards. Here are some common quality control methods used for gray cast iron castings:

1. Visual Inspection: Visual inspection is the most basic form of quality control. Inspectors visually assess castings for surface defects, such as cracks, surface roughness, porosity, and irregularities in shape or dimensions.

2. Non-Destructive Testing (NDT): NDT methods are used to detect internal defects without causing damage to the casting. Common NDT techniques include:

- Radiographic Testing (X-ray or Gamma-ray): This method can reveal internal defects, porosity, and discontinuities.

- Ultrasonic Testing: Ultrasonic waves are used to detect internal flaws, voids, and inclusions within the casting.

- Magnetic Particle Testing: Detects surface and near-surface defects by applying a magnetic field and using magnetic particles to highlight flaws.

- Penetrant Testing: A liquid penetrant is applied to the casting surface, and the excess is wiped off. The penetrant is drawn into surface-breaking defects, making them visible under UV light.

3. Dimensional Measurement: Dimensional accuracy is crucial for proper fit and function. Techniques such as coordinate measuring machines (CMM), laser scanning, and precision gauges are used to measure and verify the dimensions of castings against specifications.

4. Metallographic Analysis: Metallography involves preparing thin sections of the casting, polishing them, and examining them under a microscope to analyze the microstructure. This helps identify defects, assess material properties, and ensure proper heat treatment.

5. Hardness Testing: Hardness tests determine the hardness of the casting’s surface and core. Different methods, such as Brinell, Rockwell, and Vickers hardness tests, are used to evaluate hardness, which correlates with mechanical properties.

6. Chemical Analysis: Chemical composition analysis ensures that the casting material meets the required specifications. This can be done using techniques like spectroscopy, X-ray fluorescence (XRF), or energy-dispersive X-ray spectroscopy (EDS).

7. Ultrasonic Thickness Testing: This method measures the thickness of the casting’s walls and sections to ensure uniformity and structural integrity.

8. Pressure Testing: Pressure testing involves subjecting the casting to a pressurized fluid to identify leaks or weak points in the component.

9. Impact and Tensile Testing: These tests determine the mechanical properties, such as impact resistance and tensile strength, of castings.

10. Mechanical Properties Testing: Other mechanical properties, such as yield strength, elongation, and modulus of elasticity, are evaluated to ensure the casting’s performance under different loads.

11. Dye Penetrant Testing: This method uses a colored dye to detect surface cracks and defects that may not be visible to the naked eye.

12. Microstructural Evaluation: Microscopic examination of the casting’s microstructure helps assess the uniformity of graphite flakes and matrix structure.

Applying a combination of these quality control methods helps ensure that gray cast iron castings meet the required standards and specifications. These methods can identify defects, verify material properties, and validate dimensional accuracy, ultimately ensuring the overall quality and performance of the castings.

Chapter 11: Considerations for Environmental Protection and Sustainability of Gray Cast Iron Castings

Environmental protection and sustainability are crucial considerations in any manufacturing process, including the production of gray cast iron castings. Here are some key considerations to ensure that the production of gray cast iron castings is environmentally friendly and sustainable:

- Material Selection:

- Choose recycled materials whenever possible. Using recycled iron scrap reduces the need for extracting and processing new raw materials, saving energy and reducing environmental impact.

- Energy Efficiency:

- Implement energy-efficient technologies and processes in the production of gray cast iron. This can include optimizing furnace operations, utilizing efficient melting techniques, and minimizing energy waste.

- Emission Control:

- Employ emission control technologies to reduce pollutants released during the casting process, such as dust, fumes, and gases. Proper ventilation and filtration systems can help mitigate environmental impacts.

- Waste Reduction and Recycling:

- Develop strategies for minimizing waste generation during casting operations. Implement recycling programs for sand, metal scraps, and other materials used in the process.

- Green Sand Systems:

- Opt for environmentally friendly sand systems that reduce waste generation and energy consumption. Consider using binders and additives that are more sustainable and biodegradable.

- Water Management:

- Implement water conservation measures and proper wastewater treatment to minimize water consumption and prevent contamination.

- Eco-Friendly Coatings:

- Use environmentally friendly coatings for molds and cores that minimize emissions during the casting process.

- Sustainable Packaging and Transport:

- Consider using sustainable packaging materials and optimizing transportation routes to reduce the carbon footprint associated with shipping castings.

- Lean Manufacturing Principles:

- Implement lean manufacturing practices to minimize waste, improve efficiency, and reduce energy consumption.

- Lifecycle Analysis:

- Conduct lifecycle analyses to evaluate the environmental impact of the entire production process, from raw material extraction to end-of-life disposal. Identify areas for improvement and implement changes accordingly.

- Renewable Energy Sources:

- Consider using renewable energy sources, such as solar or wind power, to reduce the carbon footprint of the casting process.

- Collaboration and Certification:

- Collaborate with environmental agencies and industry organizations to adopt best practices and receive certifications for sustainable manufacturing processes.

- Employee Training:

- Educate employees about the importance of environmental protection and sustainability, encouraging them to contribute to greener practices.

- Innovation and Research:

- Invest in research and development to explore new technologies, materials, and processes that can further enhance the environmental sustainability of gray cast iron casting.

By incorporating these considerations into gray cast iron casting processes, manufacturers can contribute to environmental protection, reduce waste, conserve resources, and promote sustainable practices within the industry.