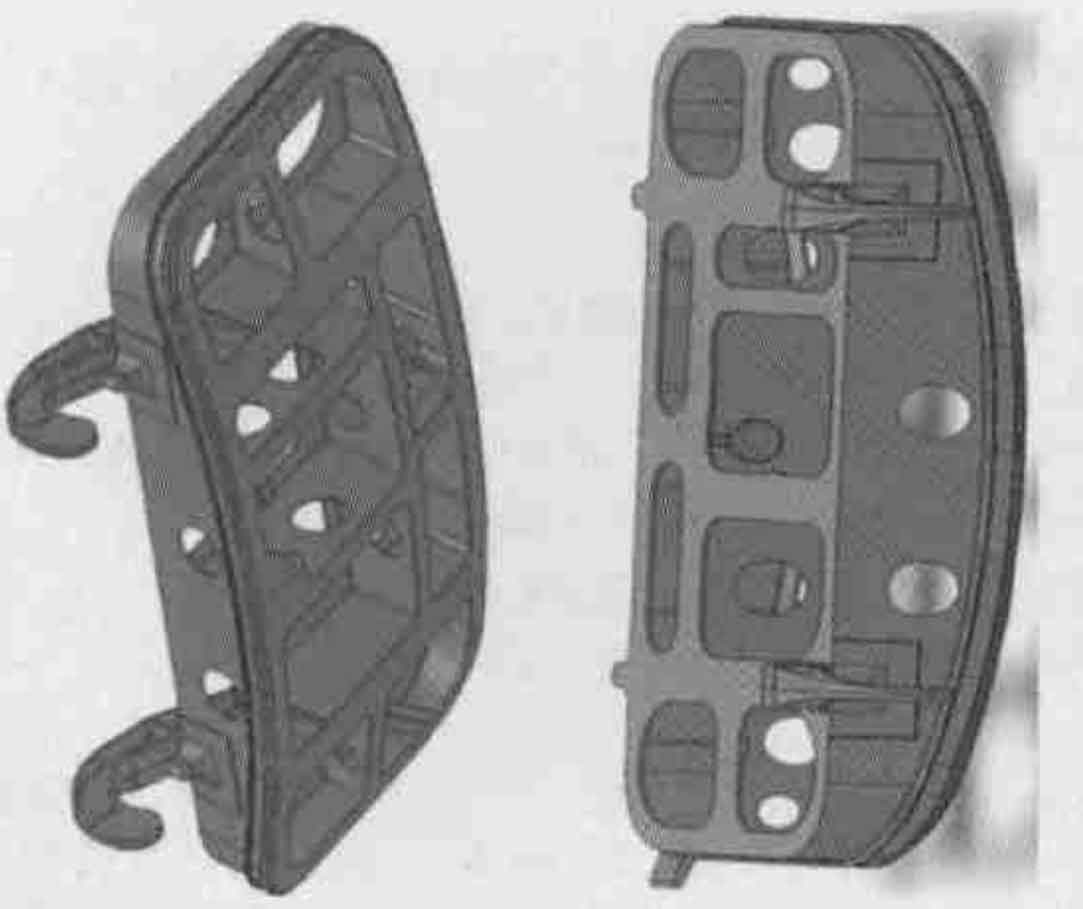

The hatch sand casting is a key structural member of aluminum alloy for aircraft. The outline dimension of fad hatch sand casting is 667 mm × 335 mm × 208 mm, with the characteristics of large (sand casting surface area of 10 769.67 cm) 2 and thin wall (overall wall thickness of 2 mm). The three-dimensional diagram of sand casting is shown in the figure.

Technical requirements and process difficulties:

(1) Sand castings are made of d357 aluminum alloy in American SAE ams4241 aerospace material specification, and there is no aluminum alloy brand equivalent to d357 in China;

(2) With thin-walled structure, the wall thickness is only 2 mm, and the dimensional accuracy of sand castings is controlled in the range of – 0.5 ~ 0.7 mm, so it is very difficult to fill the mold and ensure the dimensional accuracy;

(3) The mechanical properties of the body at the intersection of reinforcement bars of sand mold castings shall be RM ≥ 345mpa, Rp0.2 ≥ 276mpa, a ≥ 5%;

(4) Sand castings have many places with sudden wall thickness transition, which is difficult to feed and easy to cause loose defects;

(5) Welding repair is not allowed for the designated parts of sand castings, and the welding area of non designated parts is allowed to be 10mm × Welding repair within 10mm;

(6) The internal quality requirements of hatch sand castings meet the standard requirements of BAC 5652 inspection specification for sand castings in Boeing process inspection specification, which is higher than the requirements of class I sand castings in Hb 963 aluminum alloy sand castings.